3D Modeling in Product Design: Transforming Ideas into Reality

Published on: September 28, 2024

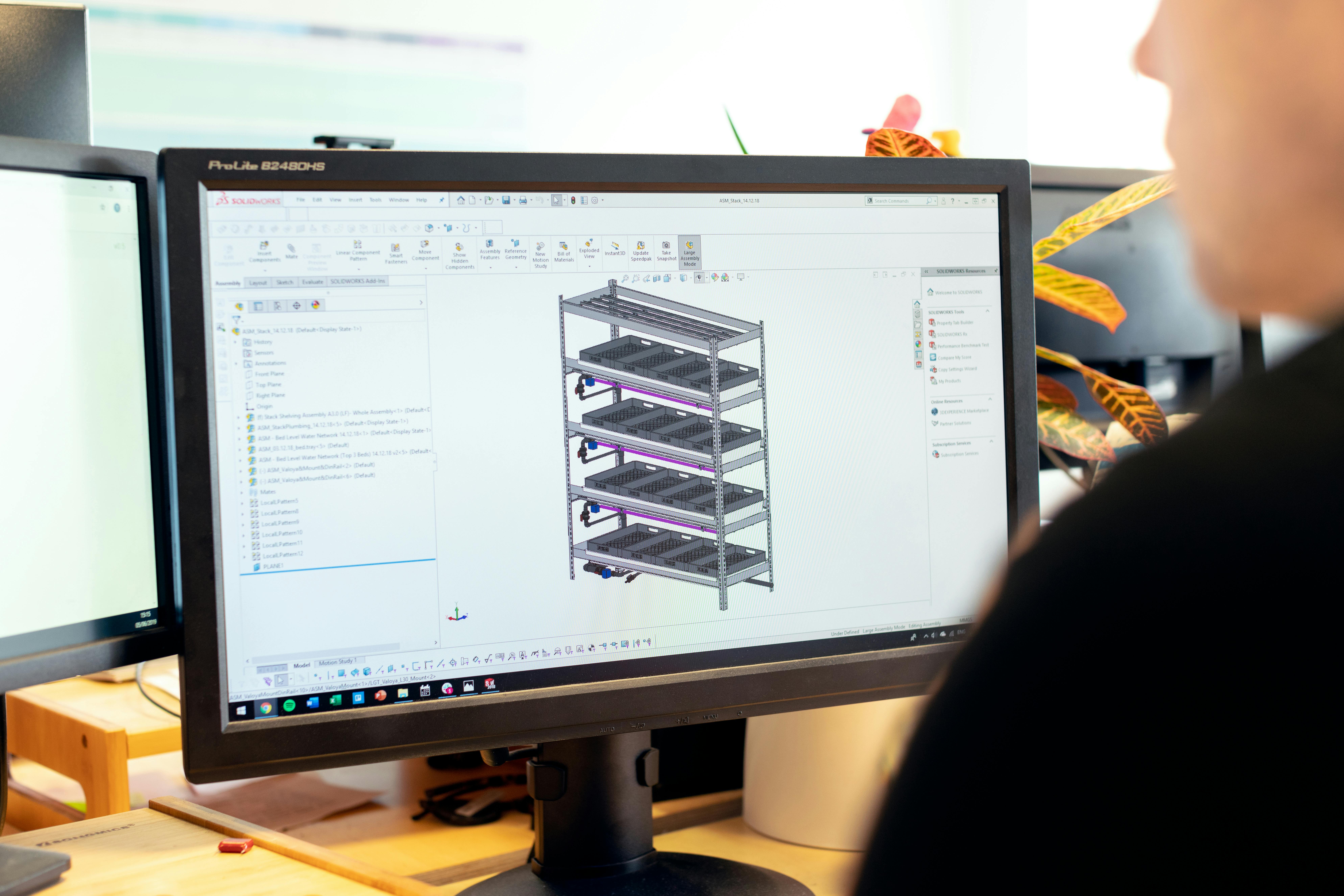

The world of product design is undergoing a revolution, driven by innovations in 3D modeling technology. No longer are designers constrained by 2D drawings, sketches, or even physical prototypes in the initial phases of product development. With the advent of sophisticated 3D modeling tools, product design has evolved into an arena of endless possibilities, giving designers the power to bring their visions to life with remarkable accuracy and depth. This transformation is pushing the boundaries of creativity, efficiency, and industry standards, turning once-distant ideas into feasible, tangible products.

In this article, we delve into how 3D modeling is revolutionizing the product design process, from initial conception to final realization. We'll explore the tools and techniques used, the impact on industries, and how 3D modeling is fostering collaboration and innovation in unprecedented ways.

The Basics of 3D Modeling in Product Design

3D modeling involves creating three-dimensional representations of objects using specialized computer software. Unlike traditional 2D sketches or blueprints, 3D models provide a realistic view of an object, allowing designers, engineers, and stakeholders to interact with and visualize the design in more dynamic ways. The digital prototypes created through 3D modeling give a far more accurate representation of size, shape, surface texture, and other vital aspects, ultimately leading to better decision-making.

At the heart of 3D modeling are CAD (Computer-Aided Design) software tools like Autodesk Fusion 360, SolidWorks, Blender, and Rhino. These tools enable designers to create highly detailed models with precise measurements and surface finishes, leading to prototypes that can be manufactured with minimal modifications. Furthermore, integrating 3D modeling into the product design workflow enhances visualization and fosters better communication with stakeholders, reducing the risk of misunderstandings and costly design changes later in the production cycle.

How 3D Modeling Transforms the Design Process

Enhanced Visualization and Conceptualization

One of the key benefits of 3D modeling in product design is its ability to enhance visualization. Designers can move beyond paper sketches to create interactive 3D models that stakeholders can view from any angle. This not only helps in visualizing complex concepts but also aids in conceptualizing how various components will work together in a final product.

In traditional design workflows, concepts were usually presented as sketches or 2D technical drawings, leaving much to the imagination of stakeholders or clients. By contrast, 3D models help bridge this communication gap by offering visual clarity, with elements like texture, lighting, and environmental context, which make the design comprehensible to both technical and non-technical audiences.

For example, an automotive designer can use 3D modeling to depict a concept car's aesthetic features as well as internal mechanical components. This allows the entire team to understand the design goals clearly—from aesthetics to functionality—early in the development process.

Iterative Prototyping and Faster Design Cycles

The speed at which iterations can be made is a critical advantage of 3D modeling in the product design process. Iterative prototyping allows designers to quickly make changes, visualize the impact, and refine their models. Instead of manually recreating parts for each iteration, designers can tweak the existing digital model, thus significantly reducing the time required to achieve a finished product.

By using rapid prototyping techniques, like 3D printing, physical models can also be created directly from the digital 3D model. This integration of digital and physical prototyping reduces turnaround time and allows for continuous improvement, as multiple iterations can be tested for fit, form, and function in real time.

Simulations and Testing in Virtual Environments

In addition to visualizing the appearance of a product, 3D modeling also provides the capability to perform simulations, enabling designers to test a product virtually before moving on to costly manufacturing processes. Structural simulations, stress analysis, and thermal simulations are among the many tests that can be performed to assess a product's performance in various scenarios.

Take, for instance, the case of designing an aerospace component. Through 3D modeling and simulation, designers can identify potential weaknesses and verify tolerances. Any inconsistencies or issues can be detected in the digital model, allowing modifications to be made before building a physical prototype. This not only saves costs but also ensures a safer, more reliable product in the end.

Improved Collaboration

3D modeling encourages seamless collaboration between team members, as well as stakeholders, suppliers, and customers. Digital models can be shared through online platforms or cloud-based solutions, allowing feedback to be gathered and changes to be implemented in real time. Cloud-based CAD platforms like Onshape enable collaboration at every step of the design process, with multiple designers able to work simultaneously on different components or aspects of a project.

This collaborative approach has proven beneficial for companies with distributed design teams, or when working with partners across the globe. The digital nature of 3D modeling facilitates efficient communication, ensuring that every stakeholder has a clear understanding of the product being developed.

Customization and Personalization

One of the most exciting possibilities brought about by 3D modeling is the ability to easily customize products. Designers can create parametric models, where the dimensions and certain features can be easily altered according to specific requirements. This opens up opportunities for product personalization, meeting the growing demand for unique and custom items.

3D modeling combined with digital manufacturing techniques, such as 3D printing, has significantly impacted industries that benefit from customization. In healthcare, for example, prosthetic limbs and dental implants can be custom-designed to fit individual patients precisely, enhancing comfort and functionality. In consumer products, customers are offered the opportunity to choose specific styles, shapes, or configurations, all of which can be adjusted through simple modifications of the digital model.

The Tools Empowering 3D Modeling

A plethora of software tools are available for 3D modeling, each suited for specific industries or types of products. Here are some of the most popular and powerful tools used by designers today:

Autodesk Fusion 360

Autodesk Fusion 360 is a cloud-based 3D modeling software known for its versatility and ease of use. It integrates 3D CAD, CAM, and CAE tools into one platform, making it ideal for product design and manufacturing. Fusion 360's collaboration features also enable teams to easily share models and work simultaneously on projects.

SolidWorks

SolidWorks is another leading CAD software used widely for product design. It offers parametric modeling, allowing for precise adjustments, and is particularly popular in the engineering and manufacturing industries. The software's integration of simulations, such as structural analysis, has made it a go-to choice for projects requiring high accuracy.

Blender

Blender is a free, open-source tool known for its diverse capabilities. Although commonly used in animation and visual effects, Blender is also gaining popularity in product design for its robust modeling features. Blender's flexibility, combined with an active online community, makes it a great option for both beginners and professionals.

Rhino

Rhino is renowned for its powerful surface modeling tools, allowing designers to create complex, organic forms. It is often used in product design for creating jewelry, footwear, and other products with intricate surfaces. Rhino also supports various plugins, such as Grasshopper, which enables generative design and parametric modeling, opening up new opportunities for designers to explore.

Onshape

Onshape is a cloud-based platform offering parametric modeling capabilities, with the added advantage of real-time collaboration. Onshape allows multiple designers to work on the same model, track design changes, and get immediate feedback, making it an ideal choice for teams working remotely or with partners across different locations.

The Role of 3D Printing in Conjunction with 3D Modeling

3D printing is a natural extension of 3D modeling, offering the capability to turn digital models into tangible, physical objects. This has proved to be a game-changer for prototyping, enabling designers to create prototypes on-site, evaluate them, and make quick modifications if necessary.

Rapid prototyping allows companies to significantly cut costs compared to traditional methods, where creating a mold or custom prototype often required considerable resources. With 3D printing, the iterative process is streamlined—designers can identify flaws, rectify them, and quickly print updated versions, saving both time and money.

For instance, companies in the aerospace and automotive industries rely heavily on 3D printing to create functional prototypes, verify form and fit, and even produce small batches of final parts. The synergy between 3D modeling and 3D printing has accelerated innovation across industries, fostering a culture of rapid experimentation and continuous improvement.

Industry Impact: Real-World Applications

3D modeling is making an impact across multiple industries, transforming how products are designed and manufactured.

Automotive Industry

The automotive industry has embraced 3D modeling to design and refine both the aesthetics and mechanical elements of vehicles. Digital models enable engineers to create and test parts in virtual environments, ensuring compatibility and safety standards are met before physical production begins.

Consumer Goods

The consumer goods sector benefits from 3D modeling by allowing companies to create detailed, customizable products. From furniture to wearables, the ability to produce digital prototypes and visualize product variations has improved the development process, resulting in more consumer-centric products.

Healthcare

In healthcare, 3D modeling is used to create detailed models of medical devices, implants, and even organs. Surgeons can use these models to plan procedures with greater accuracy. Prosthetics and dental products can also be precisely customized, improving patient outcomes and comfort.

Aerospace

The aerospace industry uses 3D modeling to optimize parts for weight, strength, and efficiency. Complex structures, such as turbine blades and rocket components, can be simulated to evaluate their behavior under extreme conditions, reducing the risk of failure and enhancing safety.

Architecture and Construction

Architects and construction companies are using 3D modeling to create realistic building models that allow them to better understand the space and scale of projects. The ability to generate immersive 3D visualizations helps convey ideas to clients and stakeholders, making approvals easier and reducing costly changes during construction.

The Future of 3D Modeling in Product Design

As technology continues to evolve, the role of 3D modeling in product design is expected to grow even further. Innovations in artificial intelligence and machine learning are enhancing the capabilities of CAD software, allowing for predictive design, automated optimizations, and generative design—where the software itself can suggest design improvements based on specified constraints.

Generative design tools use algorithms to generate multiple design variations, each optimized for different criteria, such as weight, material cost, or strength. This process enables designers to explore more options in a shorter period, ultimately leading to more efficient and creative solutions.

Virtual Reality (VR) and Augmented Reality (AR) are also transforming 3D modeling workflows by allowing designers to immerse themselves in their creations. VR tools like Gravity Sketch allow designers to create models while wearing a VR headset, effectively bringing the design process into a 3D space where it is easier to manipulate and explore concepts.

Furthermore, with the rise of the Internet of Things (IoT), 3D modeling is becoming increasingly integrated into smart manufacturing systems. Digital twins—virtual replicas of physical systems—are being used to monitor and control products in real time, helping manufacturers predict maintenance needs and optimize performance throughout a product's lifecycle.

Challenges and Limitations of 3D Modeling

Despite the numerous benefits, 3D modeling also comes with its challenges. One key limitation is the steep learning curve associated with CAD software. For beginners, learning how to operate complex tools like SolidWorks or Fusion 360 can be daunting, often requiring substantial training or experience.

Another challenge is the computational power required to render detailed models. High-quality 3D models, especially those used for simulations, often require powerful computers to handle complex calculations and renderings without lag. For small teams or independent designers, access to this level of hardware can be a limiting factor.

Finally, while 3D modeling is immensely beneficial for prototyping, it may fall short when it comes to evaluating the real-world material properties of a product. Physical prototypes, although more expensive, are sometimes necessary to determine how a material will behave under stress or interact with other components in the real environment.

3D modeling has fundamentally changed the landscape of product design, offering a versatile, powerful tool for designers across industries. By providing enhanced visualization, enabling iterative prototyping, supporting simulations, and improving collaboration, 3D modeling is helping companies bring their ideas to life faster and more effectively than ever before.

As new technologies like AI, VR, and IoT continue to develop, the potential applications of 3D modeling will only grow, enabling designers to create even more innovative, optimized products. Though challenges like accessibility and the steep learning curve remain, the industry as a whole is moving towards making 3D modeling an essential and integral part of the product design process—truly transforming ideas into reality.

Whether you're a designer aiming to create the next groundbreaking product, an engineer focused on optimizing manufacturing processes, or simply an enthusiast excited about the possibilities of technology, 3D modeling is a vital tool that brings ideas into the physical world. As it continues to advance, the line between imagination and realization will become even more blurred, ultimately leading to a world where creativity is the only limit.