Mastering 3D Printing Materials: A Guide to Choosing the Right Filament for Your Project

Published on: December 2, 2023

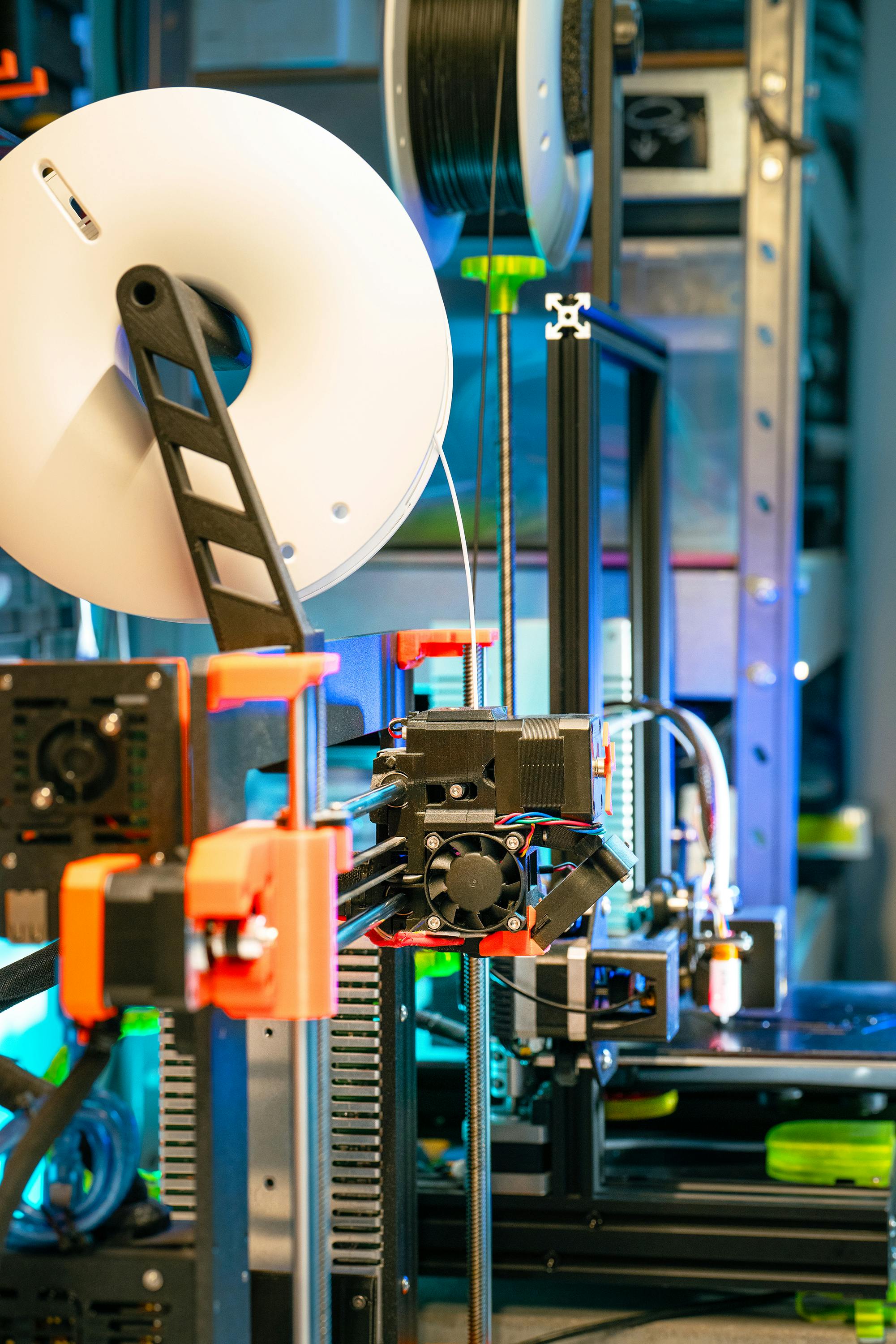

3D printing has revolutionized the way we think about creating prototypes, custom tools, functional parts, and even art. Whether you’re a beginner just getting started or an experienced maker pushing the boundaries of what's possible, choosing the right filament can make or break your 3D printing project. With so many different materials available—each with its own properties, strengths, and weaknesses—it's crucial to understand how to select the right filament for your specific needs.

In this guide, we'll explore some of the most popular 3D printing filaments, including PLA, ABS, PETG, and resin. We'll look at the benefits and limitations of each material, provide practical advice on when to use each type, and explore the niche, specialty filaments that open up even more possibilities for your creations. By the end, you'll have a solid understanding of which filament to choose for your next project, regardless of its application—be it prototyping, functional parts, or a sustainable venture.

PLA: The Beginner's Favorite

What is PLA?

Polylactic Acid, or PLA, is one of the most popular and widely used filaments for 3D printing. It is a thermoplastic that is derived from renewable resources like corn starch or sugarcane, making it one of the most environmentally friendly filaments available. PLA is a favorite among beginners because it is easy to print, affordable, and widely available.

Properties of PLA

Ease of Use: PLA is very easy to work with, making it an ideal choice for beginners. It has a lower melting temperature, usually between 180°C and 220°C, which makes it compatible with most 3D printers without requiring a heated bed.

Strength and Durability: While PLA is relatively strong, it is not as durable as other materials like ABS or PETG. It tends to be brittle, which means it may crack or shatter under stress.

Environmentally Friendly: PLA is biodegradable under industrial composting conditions, making it a better choice for those concerned with sustainability.

Finish and Detail: PLA provides a high-quality finish with a glossy appearance, and it works well for projects where aesthetics matter.

When to Use PLA

PLA is an excellent choice for prototyping, educational purposes, and decorative items that do not require high durability. It is suitable for beginners as well as experienced makers who want an easy filament to work with. For objects like figurines, models, or lightweight parts that won't be exposed to heavy mechanical stress, PLA is the ideal material.

Limitations of PLA

PLA's main limitation is its lack of durability and flexibility. It also has a relatively low glass transition temperature (around 60°C), meaning it can deform or soften if exposed to high temperatures—for example, if left in a hot car. PLA is not suitable for outdoor applications or for functional parts that require high mechanical strength.

ABS: The Workhorse Material

What is ABS?

Acrylonitrile Butadiene Styrene, or ABS, is a strong and durable thermoplastic that is commonly used in manufacturing and industrial applications. Unlike PLA, ABS is not biodegradable, but it offers superior strength and heat resistance, making it a go-to material for functional parts.

Properties of ABS

Strength and Durability: ABS is highly durable and offers good impact resistance. This makes it suitable for creating parts that need to withstand mechanical stress.

Heat Resistance: ABS has a higher glass transition temperature than PLA, typically around 105°C, meaning it can withstand higher temperatures without deforming.

Post-Processing: ABS can be smoothed and polished using acetone, giving it a glossy finish that looks almost like injection-molded plastic. This makes it an attractive option for those who need a professional-looking result.

When to Use ABS

ABS is great for creating functional parts that need to be strong and durable, such as tool holders, automotive parts, or enclosures. If you need a part that can withstand some mechanical abuse, ABS is a good choice. It is also ideal for applications where you want to perform post-processing to achieve a professional appearance.

Challenges with ABS

Printing with ABS can be challenging, especially for beginners. It requires a heated bed to prevent warping, and ideally, an enclosure to maintain a stable temperature during printing. ABS also produces fumes that can be irritating or harmful if inhaled, so it is important to print in a well-ventilated area or use a printer with an air filter. Warping and cracking are common issues when printing with ABS, but these can be minimized with proper settings and an enclosed printer.

PETG: The Versatile Hybrid

What is PETG?

Polyethylene Terephthalate Glycol (PETG) is a popular filament that offers a balance of the properties found in PLA and ABS. It is easy to print like PLA, but it also has the strength and durability closer to that of ABS. PETG is also known for its resistance to moisture and chemicals, making it a versatile option for a wide range of projects.

Properties of PETG

Ease of Use: PETG is relatively easy to print and doesn’t require a heated enclosure like ABS. It typically prints at temperatures between 220°C and 250°C, and a heated bed helps with adhesion.

Durability: PETG is strong, impact-resistant, and more flexible than PLA, making it an excellent material for functional parts. It also has better heat resistance compared to PLA.

Transparency: PETG is available in transparent versions, making it a great choice for projects that require a see-through finish, such as protective covers or containers.

When to Use PETG

PETG is ideal for functional parts that require both strength and flexibility. It is often used for parts that will be exposed to moisture, such as outdoor parts or containers. PETG is also a great choice for those who want to combine the ease of printing that comes with PLA with the durability and strength of ABS.

Limitations of PETG

One of the challenges with PETG is stringing—the tendency for the filament to create small threads or “strings” between different parts of the print. Adjusting retraction settings can help minimize stringing, but it may take some experimentation to get it right. Additionally, PETG tends to bond very well to the print bed, so it’s important to use a release agent or flexible build plate to avoid damaging your printer.

Resin: High Detail and Smooth Finishes

What is Resin?

Resin printing, also known as SLA (Stereolithography) or DLP (Digital Light Processing) printing, uses liquid photopolymer resin that is cured layer-by-layer using UV light. Unlike filament-based FDM printing, resin printing produces parts with exceptionally high detail and smooth surfaces.

Properties of Resin

High Detail: Resin printers produce highly detailed parts, making them ideal for applications like jewelry, figurines, and medical models. The resolution of resin prints is significantly higher than that of FDM prints.

Smooth Surface Finish: Resin prints have a very smooth surface finish, which makes them ideal for display pieces and intricate models.

Versatility: Different resins are available for different purposes, such as standard resin, tough resin, flexible resin, and even dental resins.

When to Use Resin

Resin is perfect for applications where detail and surface finish are critical, such as jewelry, miniatures, and intricate art pieces. It is also used for creating functional prototypes that require a smooth surface and high accuracy. For medical models and dental applications, resin printing provides the necessary precision and material properties.

Challenges with Resin

Resin printing can be more complicated than FDM printing. Resin is messy and requires post-processing, including washing the print in isopropyl alcohol and curing it with UV light. Safety is another consideration, as resins can be toxic and require gloves and proper ventilation to handle. Resin printing is generally more expensive than filament printing, both in terms of the printer itself and the consumables.

Specialty Filaments: Expanding the Possibilities

Beyond the most common materials, there are a variety of specialty filaments that can be used for more advanced projects or specific needs. Let's look at some of these filaments and what they bring to the table.

Nylon

Nylon is a strong and flexible filament that is ideal for functional parts that require toughness and wear resistance. It is often used for gears, bearings, and mechanical parts that need to withstand friction and impact. Nylon is hygroscopic, meaning it readily absorbs moisture, so proper storage is essential to ensure successful prints.

TPU (Flexible Filament)

TPU, or Thermoplastic Polyurethane, is a flexible filament that allows you to create parts with rubber-like elasticity. TPU is perfect for applications that require flexibility, such as phone cases, gaskets, and wearable items. Printing with TPU can be challenging, as it requires slower print speeds and specific extruder settings, but the results are worth the effort for projects that demand flexibility.

Wood-Filled Filaments

Wood-filled filaments are PLA-based filaments mixed with fine wood particles to give the printed part a wood-like appearance and texture. These filaments are great for decorative items and artistic projects, as they provide a natural, organic look that is difficult to achieve with standard filaments.

Carbon Fiber Reinforced Filaments

Carbon fiber filaments are composites that combine a base material, such as PLA or Nylon, with carbon fiber strands to increase strength and stiffness. These filaments are perfect for parts that need to be lightweight yet incredibly strong, such as drone frames or structural components. However, carbon fiber filaments are abrasive and can wear down standard brass nozzles, so a hardened steel nozzle is recommended.

Metal-Filled Filaments

Metal-filled filaments are composites that contain fine metal powders mixed with a base material like PLA. These filaments allow you to create parts that look and feel like metal, adding a unique aesthetic to your prints. They are heavier than standard filaments and can be polished to achieve a shiny, metallic finish. However, they can be challenging to work with and require careful calibration.

Choosing the Right Filament for Your Project

Selecting the right filament for your 3D printing project depends on several factors, including the intended application, desired properties, and the capabilities of your printer. Here are some key considerations to help you make the right choice:

Strength and Durability: For parts that need to withstand stress or impact, ABS, PETG, or Nylon are good choices. Carbon fiber reinforced filaments are also an option for high-strength, lightweight parts.

Ease of Printing: For beginners or for projects where ease of printing is a priority, PLA is the best choice. It is easy to work with, doesn’t require a heated bed, and produces consistent results.

Flexibility: For flexible parts, such as gaskets or wearable items, TPU is the filament of choice. Its elasticity makes it ideal for applications that require a rubber-like material.

Aesthetic Finish: If surface finish and detail are important, resin printing offers the best results. For a natural look, wood-filled filaments provide an organic appearance that’s hard to replicate.

Temperature and Environmental Considerations: For outdoor use or applications that require resistance to high temperatures, ABS or PETG are suitable options. PLA, on the other hand, is not suitable for high-temperature environments as it softens easily.

Tips for Getting the Most Out of Your Filament

Storage: Proper storage is crucial for maintaining the quality of your filament. Materials like Nylon and TPU are hygroscopic and can absorb moisture from the air, which can lead to poor print quality. Store your filaments in an airtight container with desiccant to keep them dry.

Printer Settings: Always check the recommended print settings for your filament, including nozzle temperature, bed temperature, and print speed. These settings can vary significantly between different types of filaments and even different brands of the same material.

Experimentation: Don’t be afraid to experiment with different filaments to find the one that works best for your project. Each material has its own unique properties, and sometimes a bit of trial and error is necessary to get the best results.

The world of 3D printing materials is vast and continually evolving. From the beginner-friendly PLA to the tough and durable ABS, the versatile PETG, and the highly detailed resin, there is a filament for every application. Specialty filaments like Nylon, TPU, and wood-filled materials expand the possibilities even further, allowing you to create parts that are functional, flexible, or simply beautiful.

Choosing the right filament for your project requires an understanding of the material properties and the demands of your application. Whether you are creating a prototype, a functional tool, or a piece of art, selecting the right filament is key to achieving a successful print. With the information provided in this guide, you’re now well-equipped to choose the best filament for your next 3D printing adventure. Happy printing!