Large-Scale 3D Printing: Revolutionizing Construction and Infrastructure

Published on: November 16, 2024

The construction industry, one of the most labor-intensive and resource-consuming sectors, is on the brink of a transformation thanks to advancements in large-scale 3D printing technology. While 3D printing has been around for decades, its application in construction has recently started to take off, promising to revolutionize the way we build homes, offices, and even infrastructure. This technology offers not only a way to build faster but also more cost-effectively, sustainably, and with greater architectural freedom. In this article, we explore the technologies behind large-scale 3D printing, how it's currently used in construction, and what the future holds for this cutting-edge approach.

A Glimpse into the Evolution of 3D Printing

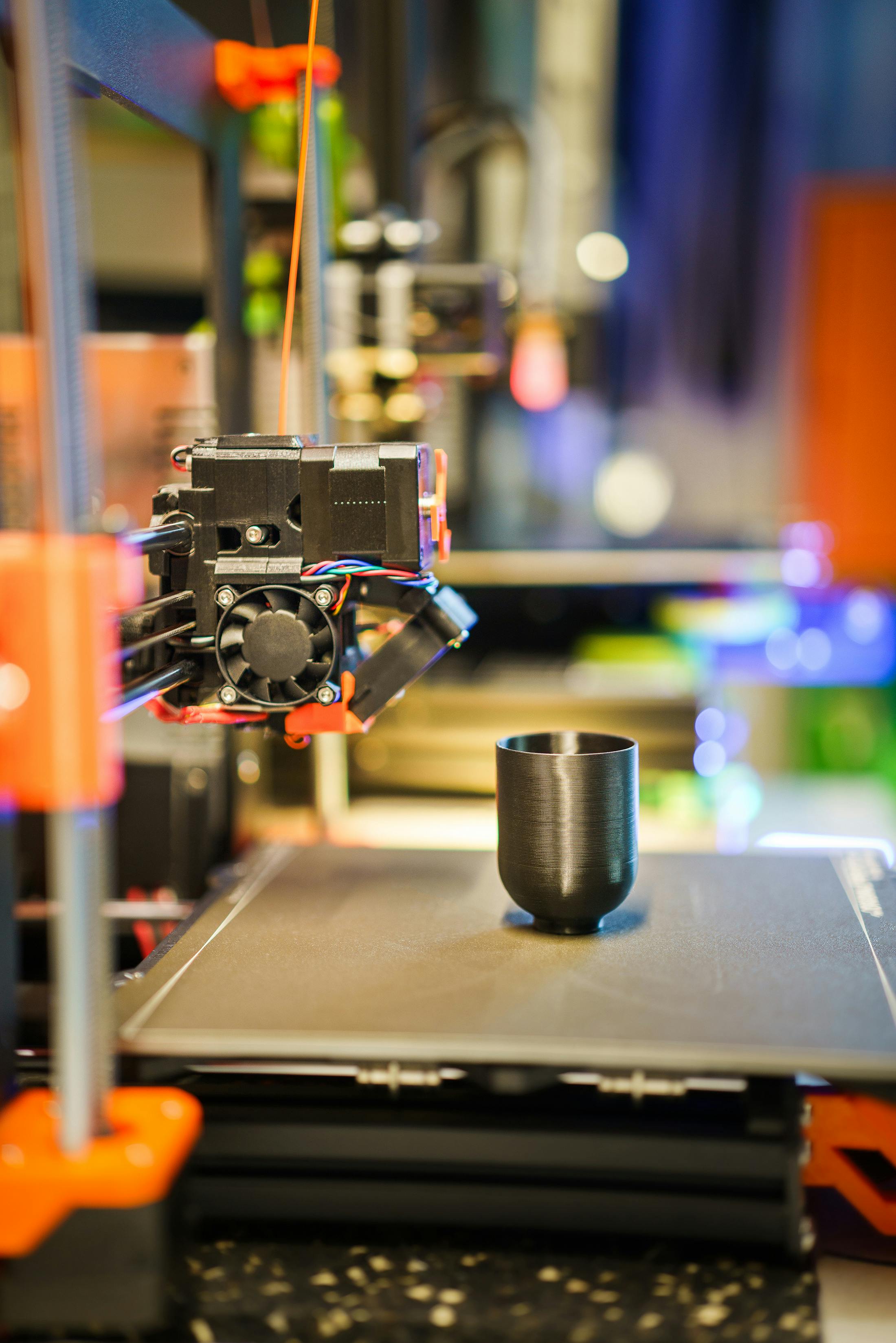

3D printing, also known as additive manufacturing, was first conceptualized in the 1980s and initially found its footing in prototyping and small-scale production. It wasn’t long before companies and inventors recognized the potential of scaling up 3D printing for construction. Unlike traditional construction methods, where materials are cut and shaped, often generating waste, 3D printing is an additive process that builds structures layer by layer. This drastically reduces waste, makes efficient use of resources, and enables a higher degree of precision.

When applied to large-scale construction, 3D printing can create complex structures with ease, integrating sophisticated designs that would be difficult or prohibitively expensive to achieve through traditional means. This opens up a world of possibilities for unique architectural features, optimizing space usage, and even enhancing energy efficiency.

Current Applications of Large-Scale 3D Printing in Construction

3D Printed Housing

Perhaps the most headline-grabbing application of large-scale 3D printing is in residential housing. Across the world, we are seeing the emergence of affordable, 3D-printed homes that are constructed in a matter of days. For instance, companies like ICON, Mighty Buildings, and Apis Cor are pioneering 3D-printed homes with the promise of reducing labor costs and providing affordable housing solutions to communities in need.

The process typically involves printing the walls and structural components of a house, while finishing work—such as electrical wiring and plumbing—is completed using traditional methods. The concrete-based materials often used in 3D printing housing units are more sustainable than conventional materials since they can be formulated to minimize waste and use recycled components.

These homes are particularly appealing in areas facing housing crises or regions affected by natural disasters, where rapid, cost-effective building solutions are desperately needed. By reducing the need for extensive labor and minimizing construction time, 3D printing has the potential to meet housing demands more efficiently than ever before.

Infrastructure Projects

Beyond residential construction, 3D printing has started making inroads into infrastructure projects. Bridges, pavilions, and even entire public spaces have been constructed using large-scale 3D printers. A notable example is the 3D-printed pedestrian bridge in Madrid, Spain, designed by Acciona, which spans 12 meters and was made using a composite of concrete and thermoplastic materials.

3D-printed bridges offer several advantages, including reduced construction costs, faster deployment, and the ability to create complex and organic shapes that blend seamlessly into urban environments. Additionally, 3D-printed components can be fabricated off-site and then assembled at their final location, significantly reducing disruption in crowded urban areas.

Disaster Relief and Temporary Shelters

One of the most promising applications of 3D printing in construction is in disaster relief. In areas struck by earthquakes, floods, or other natural disasters, rapid response is crucial. 3D printing technology allows for the creation of temporary shelters that can be deployed quickly to house those affected by disasters.

Organizations like New Story and ICON are actively using 3D printing to provide emergency housing, focusing on vulnerable populations in developing nations. The flexibility and speed of large-scale 3D printing make it ideal for constructing both temporary and permanent shelters, providing a lifeline to communities during times of crisis.

Benefits of Large-Scale 3D Printing in Construction

Cost Efficiency

One of the key advantages of 3D printing in construction is the potential for significant cost reductions. Traditional construction projects require a substantial workforce, a lengthy construction timeline, and expensive materials. By comparison, 3D printing requires fewer workers, as the majority of the work is automated. This can translate to cost savings of up to 50% for labor-intensive projects.

The additive manufacturing process also reduces material waste by precisely dispensing material where needed, which not only saves money but also reduces the environmental footprint. Many construction 3D printers utilize concrete or composites, which can be formulated to include recycled materials, further driving down costs.

Speed of Construction

In traditional construction, the timeline for building even a simple structure can extend over several months due to logistical issues, weather delays, and the coordination of multiple tradespeople. Large-scale 3D printers can produce the basic framework of a building in just a few days. A well-coordinated project can have a fully printed home ready for occupancy within a few weeks, including finishing work. This speed is particularly advantageous in scenarios where time is of the essence, such as in emergency housing projects.

Sustainability

Sustainability has become a key focus of modern construction practices, and 3D printing can play a significant role in reducing the industry's carbon footprint. Traditional construction is notorious for generating massive amounts of waste—from unused building materials to demolished components. Additive manufacturing, on the other hand, is inherently more efficient, using only the material necessary for each part of the build.

Furthermore, 3D-printed structures can be designed with energy efficiency in mind. Curved walls, for example, can minimize heat loss, while other architectural elements, such as insulation-filled cavities, can be seamlessly integrated during the printing process.

Design Flexibility

Large-scale 3D printing allows architects and designers to break free from the constraints of traditional construction techniques. With 3D printing, complex geometric shapes, curves, and intricate detailing are achievable without a significant cost increase. This opens up new possibilities for creative, aesthetically pleasing designs that would be difficult to realize using conventional methods.

Buildings can be designed with optimized layouts, incorporating features that enhance natural lighting, airflow, or energy efficiency. Additionally, the potential for customization means that each structure can be uniquely tailored to suit its environment or the preferences of its occupants, providing both functional and artistic advantages.

Reduced Labor Requirements

Labor shortages are a major challenge facing the construction industry worldwide. With an aging workforce and fewer young people entering the trades, the need for a solution is pressing. Large-scale 3D printing can alleviate some of this pressure by reducing the amount of manual labor required for construction. The use of automation means that fewer specialized workers are needed on-site, allowing construction companies to reallocate their workforce to other tasks or projects.

Challenges Facing Large-Scale 3D Printing in Construction

While the potential benefits of 3D printing in construction are vast, there are still several challenges that need to be addressed to bring this technology into the mainstream.

Regulatory and Code Compliance

Building codes and regulations are designed with traditional construction methods in mind. Introducing 3D printing into the mix requires significant adjustments to these standards, which vary greatly from region to region. Ensuring that 3D-printed buildings meet safety requirements and building codes can be a complex process, as there is currently a lack of comprehensive regulations tailored to this technology.

For large-scale 3D printing to become widely adopted, governments and regulatory bodies must work with industry leaders to develop new standards and certifications. These standards should address structural integrity, fire resistance, material quality, and other key safety concerns, ensuring that 3D-printed buildings are as safe as those constructed using traditional methods.

Material Limitations

Most of the large-scale 3D printers used in construction today rely on concrete-based materials, which have certain limitations. While concrete is versatile and widely available, it may not be suitable for all climates or all types of buildings. The heavy reliance on concrete also raises questions about the environmental impact, as cement production is a significant source of CO2 emissions.

Ongoing research is focused on developing alternative materials that are better suited for specific applications and have a lower environmental impact. Examples include bio-based materials, recycled plastics, and geopolymer cements. Overcoming the current limitations of 3D printing materials is crucial for expanding the use of this technology across a wider range of construction projects.

High Initial Costs

The upfront costs associated with large-scale 3D printing can be a barrier to widespread adoption. While the cost of individual projects may be lower due to reduced labor and materials, the investment required to purchase and maintain 3D printing equipment is significant. Many construction firms, particularly smaller ones, may not have the financial resources to invest in this technology without government incentives or partnerships.

Additionally, training workers to operate 3D printers and manage the associated software requires time and resources. Overcoming these initial hurdles is essential to encourage more widespread use of 3D printing in construction.

Limited Awareness and Resistance to Change

As with any new technology, there is often resistance to change within established industries. Many stakeholders in the construction industry may be unfamiliar with 3D printing or skeptical of its capabilities. Convincing contractors, architects, and clients of the reliability and benefits of 3D printing requires education and demonstration projects that highlight its potential.

In some cases, there may also be cultural resistance to using unconventional building techniques, particularly in regions where traditional methods have been used for centuries. Overcoming this resistance will require collaboration between technology developers, construction professionals, and local communities to demonstrate the value of 3D printing.

The Future of Large-Scale 3D Printing in Construction

Despite the challenges, the future of large-scale 3D printing in construction looks incredibly promising. As the technology continues to mature, we can expect to see more innovation, lower costs, and broader adoption. Here are some potential trends that could shape the future of 3D-printed construction:

Expansion into Commercial and High-Rise Buildings

Currently, most 3D-printed buildings are residential homes or small infrastructure projects. However, as the technology develops, it could be scaled up for larger commercial buildings and even high-rise structures. The ability to fabricate modular components off-site and assemble them on-site could make 3D printing a viable option for larger-scale developments, reducing construction time and labor requirements.

Increased Use of Sustainable Materials

The environmental impact of construction is a significant concern, and 3D printing could help address this issue by incorporating more sustainable materials. Researchers are exploring the use of natural and recycled materials in 3D printing, which could further reduce the carbon footprint of construction projects. For example, using locally sourced clay or recycled plastic as a printing material could significantly improve the sustainability of 3D-printed buildings.

Integration with Smart Technologies

Large-scale 3D printing can be combined with other emerging technologies to create smart, efficient buildings. By integrating sensors, IoT devices, and automation during the construction process, buildings can be made smarter from the ground up. This could include features such as embedded temperature sensors, automated climate control systems, and even the integration of renewable energy systems like solar panels into the building’s design.

Addressing Housing Shortages

With urban populations growing rapidly, housing shortages have become a pressing issue in many parts of the world. 3D printing could provide a viable solution by enabling the rapid construction of affordable housing. In regions facing acute housing crises, governments and non-profits may increasingly turn to 3D printing to provide scalable and cost-effective solutions.

Projects like those undertaken by ICON in collaboration with housing non-profits are already providing proof of concept, showcasing how entire communities can be built using 3D printing. As the technology advances, its application in addressing housing shortages is likely to become more common, providing a safe and dignified living environment for those in need.

Hybrid Construction Approaches

The future of construction may involve hybrid approaches that combine the best of both traditional and 3D printing methods. For example, while large-scale 3D printers can be used to print structural elements, traditional methods may be used for finishing, installation, and other detailed work. This hybrid approach allows builders to capitalize on the strengths of each method, resulting in more efficient and flexible construction processes.

Increased Collaboration Across Industries

The development and adoption of large-scale 3D printing in construction will require collaboration across various industries, including construction, technology, materials science, and government. Public-private partnerships will be essential to drive innovation and provide the necessary funding and support for pilot projects.

Furthermore, collaboration between architects and 3D printing technology developers will be crucial in realizing the full potential of this approach. Architects must design with 3D printing in mind, taking advantage of the unique possibilities offered by additive manufacturing to create structures that are not only functional but also aesthetically distinctive.

Large-scale 3D printing has the potential to revolutionize the construction industry by addressing some of its most pressing challenges: high costs, labor shortages, waste, and the need for rapid, scalable solutions. From 3D-printed homes that provide affordable housing to infrastructure projects that reduce environmental impact, the applications of this technology are diverse and far-reaching.

However, there are still hurdles to overcome, including regulatory challenges, material limitations, and the high cost of entry. Addressing these challenges will require a concerted effort from governments, industry stakeholders, and technology developers.

The benefits of large-scale 3D printing—including cost efficiency, sustainability, design freedom, and speed—make it an attractive option for the future of construction. As the technology continues to evolve, we are likely to see even more innovative applications that push the boundaries of what’s possible in building and infrastructure development. The future of construction is being printed layer by layer, and it’s an exciting time to witness the transformation of this age-old industry.